Recent Projects Design and Build for Coal Preparation ...

Luscar Ltd. 1200 MTPH Coal Preparation Plant 2005. Coal Valley Mine with Heavy Media Vessel, Heavy. Edson, Canada Media Cyclone, Spiral, and Column ...

WhatsApp)

WhatsApp)

Luscar Ltd. 1200 MTPH Coal Preparation Plant 2005. Coal Valley Mine with Heavy Media Vessel, Heavy. Edson, Canada Media Cyclone, Spiral, and Column ...

Further chapters focus on economic factors affecting coal preparation, posttreatment of coal, coal tailings treatment, and the optimisation, simulation and control of coal preparation plants. Finally, part three considers aspects of the coal supply chain including the management approach and individual functions such as coal blending and ...

A coal preparation plant (or coal handling plant) is a place where coal is prepared for use after it has been coal is washed and resized here, before it is transported to be sold, loaded on coal transport or used locally. It is then transported to coalfired power plants, for example.

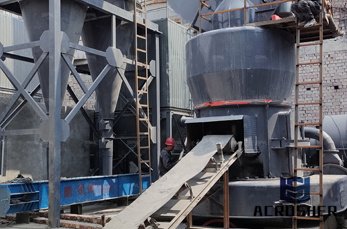

Coal Processing Coal washing plants for the crushing, sizing, washing and drying of coal to enable it to be used in power stations. Products: Modular Coal Preparation Plant (MCPP) comprising of vibratory screening equipment, fine coal slurry separator, magnetic separator, cyclone, heavy medium vessel, etc.

Single stream plants ( with one drum, one cyclone and one spiral section) have operating capacities up to 350 t/h of raw coal feed, though modules are currently under design which will enable a single stream capacity up to 450 t/h.

Add organic matter each year during soil preparation to build and maintain the soil. Be sure all plant material is turned under the soil. If organic material is added before planting a fall garden, it should be wellrotted, such as compost. Before planting, rake the soil clean and level it. Remove all sticks, rocks and other material. Row ...

Corporate Headquarters: PO Box 2648 Fairmont, WV Phone: sales

Jan 04, 2019· Coal washing is a process that is undertaken in a coal washery or coal preparation plant (CPP) where coal is refined or cleaned of impurities. Coal washing involves using water, mechanical techniques and relies on gravity and the difference of density between coal and it''s impurities which are usually more densely packed due to the fact that ...

AS Higher Rank Coal and Coke Relative Density AS 2418 Coal and Coke Glossary of Terms AS Coal preparation Higher Rank Coal Float and Sink Testing (2018 revision, in publication) AS Coal preparation –Magnetite for coal preparation plant use –Test methods Magnetite AS 5213 Density Tracers (in publication)

PVC Resin Plant Liquidation –Process Equipment, Labs, Pilot Plant Unused DWE Tubular Reactor (2) ZIRCONIUM cooler/condensers for nitric acid plants Alstom Rotary Atomizers for Flue Gas Desulfurization (DFGD) System (3) AMFBruns Cooling Screws, high temp, jkt and cored shaft for ash cooling, 900 deg. C UNUSED Acrylic Fiber Plant – 34,000 TPA

A coal breaker is a coal processing plant which breaks coal into various useful sizes. Coal breakers also remove impurities from the coal (typically slate) and deposit them into a culm coal breaker is a forerunner of the modern coal preparation plant.. Generally speaking, a coal tipple was typically used at a bituminous coal .

May 17, 2018· In fulfillment of its mission to ensure America''s security and prosperity through transformative science and technology solutions, the Department of Energy (DOE) is working to advance research and development (RD) on smallscale, modular coalbased power plants for .

Major Group 12: Coal Mining This major group includes establishments primarily engaged in producing bituminous coal, anthracite, and lignite. Included are mining operations and preparation plants (also known as cleaning plants and washeries), whether or not such plants are operated in .

Coal preparation is the process where raw coal from mine is cleaned using different, remove inorganic material (ash) thus reducing ash handling in coal plants.... Coal processing The Coal Handling and Preparation Plant, located at Bulga Coal, operates 24 hours per day, 7 days per week and has a capacity of 20Mtpa Run of Mine (ROM)....

developed, and certain operating plants canclaim tobe conducting someofthemost efficient separations inthe world, Twoother features have stimulated thedevelopment of coalpreparation technologies, namely, the shortage ofcoking coal,andthedesire tomake asmuch highgrade material aspossible from thepredominantly lowgrade reserves ofthe country.

Coal preparation. As explained above, during the formation of coal and subsequent geologic activities, a coal seam may acquire mineral matter, veins of clay, bands of rock, and igneous addition, during the process of mining, a portion of the roof and floor material may be taken along with the coal seam in order to create adequate working height for the equipment and miners.

Such preparation steps may include homogenization or sample heating. The addition of tracers or carriers prior to these steps helps to account for any analyte loss during sample preparation. Losses as Dust or Particulates When a sample is dry ashed, a fine residue (ash) is often formed. The small particles in the

Oct 18, 2013· Coal Preparation Plant General Permit Number G10D. General Permit G10D is for the Prevention and Control of Air Pollution in regard to the Construction, Modification, Relocation, Administrative Update and Operation of Coal Preparation and Processing Plants and Coal Handling Operations. This Class II General Permit G10D addresses the ...

Jan 16, 2018· Remediation before repurposing. UCS found that of 1,256 coalfired generating units ( GW) operating in 2008, some 452 units ( GW) had been shuttered by the end of 2016, 98 ( GW) had ...

Jul 11, 2017· The 582 MW Kemper County Power Plant in rural Mississippi, the largest clean coal project in the, was forced by the state to become an ordinary natural gas power plant after spending 7 .

Coal Handling Preparation Plants Heap Leach Facilities Materials Handling ... Our aim is to deliver superior coal process solutions for our clients big or small, regardless of the location. Our end to end solutions are proven to lower capital and operating costs, reduce construction time and improve plant .

Coal preparation plants remove waste material from coal by washing and concentrating. The plants may also sort and screen coal by size, and may crush the coal to facilitate handling and processing. The coal may be stored at several stages in the process of preparation and transport to the final customer.

Coal Washing Plants consist of several subprocessing modules including raw coal preparation (crushing and screening station), pre discharge rejects (rom jig, dense medium vessel/bath, rotary breaker), coal feeding and washing module (jigging or dense medium cyclones) as well as a dewatering module, coal handling module (conveyors, train/truck loading station, stacker reclaimer).

54 Coal Preparation Plant jobs available on Apply to Customer Service Representative, Senior Fitter, Development Manager and more!

WhatsApp)

WhatsApp)